- No products in the cart.

As someone who has navigated the exhilarating yet intricate world of textiles and fashion for over 15 years, I have witnessed numerous shifts, from the rise of sustainable sourcing to the surge in personalized apparel. What truly excites me, and what I consistently advise budding entrepreneurs and established brands on, is the remarkable power of custom printing. At the forefront of this revolution, especially as we approach 2025, is Direct-to-Garment (DTG) printing.

It’s no secret that the demand for unique, customized pieces is skyrocketing. People no longer desire mass-produced, identical garments; they crave individuality that reflects their personal style or brand identity. This sentiment drives the custom apparel printing market, which, according to all projections, is poised for continued impressive growth. Industry reports indicate that the direct-to-garment (DTG) market alone is expected to expand at a robust annual rate of 12% through 2025, reaching a significant global valuation.

My goal here is not only to explain what Direct-to-Garment (DTG) printing is but also to provide you with a comprehensive, insider’s perspective on why it is becoming the cornerstone for independent brands, small businesses, and even large-scale fashion houses seeking agile production. We will explore its mechanics, the undeniable benefits of DTG printing, the challenges it presents, and what the future of DTG printing may hold as we approach 2025.

Definition and Basic Concept: DTG Printing Explained

At its core, Direct-to-Garment (DTG) printing is exactly what its name suggests: it functions like an oversized inkjet printer that applies designs directly onto fabric. This method eliminates the traditional screen printing process, which requires a separate screen for each color, as well as the often-rigid texture associated with heat transfers. In DTG printing, liquid DTG inks are sprayed onto the fabric, allowing them to be absorbed directly into the fibers.

This technology enables remarkable detail and a full spectrum of colors, similar to printing a photograph on paper. As an industry veteran, I have witnessed how Direct-to-Garment (DTG) printing, when explained simply, is a game-changer for those requiring vibrant, intricate images on their custom apparel. It is especially well-suited for custom-printed hoodies and t-shirts, where complex designs are essential.

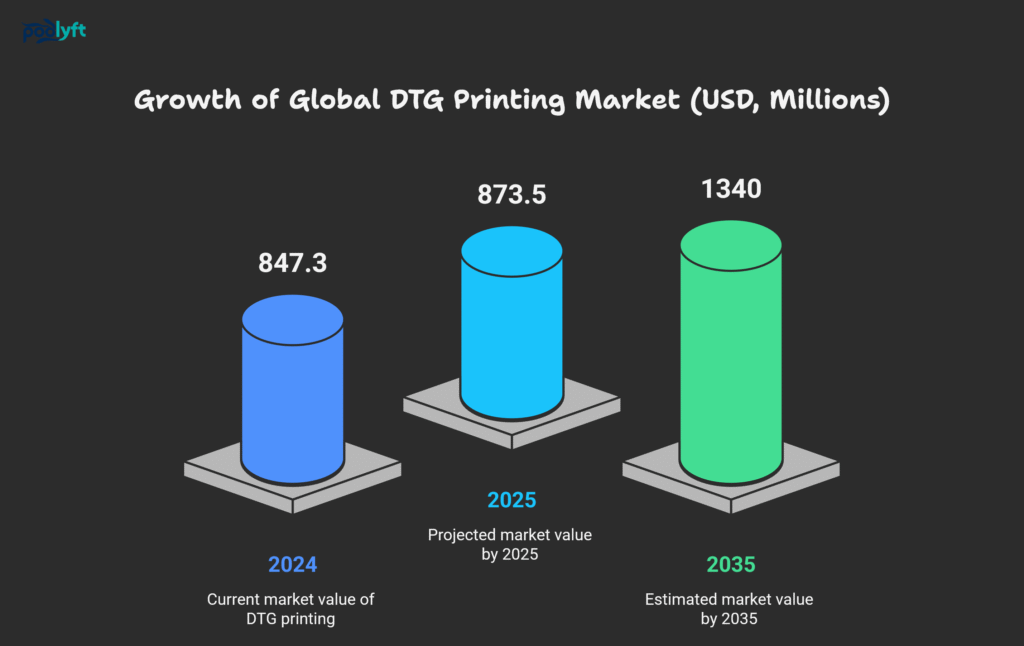

The global Direct-to-Garment (DTG) printing market, valued at approximately $847.3 million in 2024, is projected to reach $873.5 million by the end of 2025, as reported by FutureMarketInsights. This market is expected to grow at a Compound Annual Growth Rate (CAGR) of 4.4% from 2025 to 2035, ultimately reaching an estimated $1.34 billion by 2035. It is evident that DTG is reshaping the industry.

History and Development

The journey of Direct-to-Garment (DTG) printing began in 1996 with Matthew Rhome’s invention of the “Revolution,” the first commercially available DTG printer in the United States. Early DTG printers were limited to CMYK (Cyan, Magenta, Yellow, and Black) inks, which made printing on dark garments particularly challenging. The color of the fabric would often overpower the ink, resulting in dull, low-contrast prints.

A significant breakthrough occurred in 2005 with the introduction of white ink. This innovation revolutionized the industry by enabling vibrant prints on dark fabrics through the application of an opaque white base layer before adding colors. The evolution of pretreatment solutions also played a crucial role in this advancement. Initially, a manual and often inconsistent process, specialized pretreatment machines were developed to ensure proper ink bonding, particularly for white ink on dark garments, resulting in more consistent and durable outcomes.

Today, prominent brands such as Brother, Kornit Digital, Epson, Ricoh, and Mimaki Engineering have consistently innovated, introducing faster, more precise, and user-friendly machines to the market. This ongoing advancement further solidifies direct-to-garment (DTG) printing’s position in the textile industry.

How Does DTG Printing Work?

The DTG printing process is remarkably streamlined, allowing for efficient production of custom garments.

The Printing Process

Understanding how to perform Direct-to-Garment (DTG) printing is simpler than you might expect; however, mastering the technique requires a keen eye and meticulous attention to detail. The DTG printing process generally involves the following steps:

- Artwork Preparation: This is where your digital design comes to life. Preparing designs for DTG involves using graphic software (like Photoshop or Illustrator), ensuring high resolution (typically 300 DPI) and correct color profiles (CMYK for print, though DTG printers often use specific RIP software for color management). I always emphasize that a good digital file is 80% of a good print.

- Pre-treatment (for dark garments): For darker fabrics, a pre-treatment solution is applied to the garment. This solution helps the white ink (which acts as a base layer for colorful designs) adhere better and prevents it from bleeding into the dark fabric, ensuring vibrant colors and crisp lines. This step is crucial and often overlooked by beginners, leading to common DTG printing problems like dull prints.

- Loading the Garment: The apparel item is carefully loaded onto a platen, which holds it flat and taut for printing.

- The Print Cycle: The DTG printing machines, which resemble large industrial printers, then jet specialized DTG inks directly onto the fabric. For dark garments, a white underbase is printed first, followed by the color layer.

- Curing: Once printed, the garment is immediately cured using a heat press or conveyor dryer. This process bonds the ink to the fabric fibers, ensuring durability and washability. Insufficient curing is one of the quickest ways to avoid DTG printing mistakes related to print longevity.

Key equipment for DTG printing includes the DTG printer itself, a pre-treatment machine (often automated), and a heat press or conveyor dryer.

Advantages of DTG Printing

In my experience, especially when advising brands in the bustling urban fashion markets of Mumbai and Bangalore, DTG offers distinct advantages:

- Unmatched Detail and Color: Direct-to-Garment (DTG) printing excels at reproducing intricate, full-color designs, including photographic prints, with remarkable accuracy and vibrant hues. This represents a significant advancement over the restricted color palettes typically associated with screen printing.

- No Setup Fees or Screens: Unlike screen printing, direct-to-garment (DTG) printing does not require costly screens or setup fees for each color. This significantly lowers the cost of DTG printing for small orders, making it a financially feasible option for one-off prints.

- Fast Turnaround for Small Runs: For orders ranging from 1 to 50 pieces, Direct-to-Garment (DTG) printing is exceptionally efficient. You can print a design on demand, making it ideal for custom orders, prototypes, or limited-edition releases.

- Eco-Friendly Options: Many modern direct-to-garment (DTG) inks are water-based and free from heavy metals, PVC, and phthalates, making them a more environmentally friendly choice compared to some traditional textile inks. This aligns perfectly with the increasing consumer demand for sustainable fashion.

Limitations to Know

No technology is without its caveats, and DTG is no exception.

- Fabric Compatibility: Direct-to-Garment (DTG) printing is most effective on 100% cotton garments. Although advancements are being made, fabric blends—particularly those with a high polyester content—can pose challenges, resulting in less vibrant prints or inadequate ink absorption. When selecting fabric, I always recommend choosing natural fibers with a good GSM (grams per square meter) to ensure optimal color options and print quality for DTG printing.

- Cost Implications for Large Orders: Although direct-to-garment (DTG) printing is cost-effective for small batches, the per-unit prices can exceed those of screen printing for very large orders (e.g., thousands of pieces) due to slower print speeds for each garment.

- A Note on Durability and Color Matching: While direct-to-garment (DTG) printing has significantly improved, prints—especially those with a heavy white ink base—may occasionally feel slightly heavier than traditional screen prints. Correcting DTG printing errors associated with color matching necessitates careful calibration and a thorough understanding of your raster image processor (RIP) software.

To provide some context, here is a brief comparison:

| Feature | DTG Printing | Screen Printing |

|---|---|---|

| Best For | Small runs, complex designs, full-color photos | Large runs, simple designs, spot colors |

| Setup Cost | Low (no screens) | High (per screen/color) |

| Detail | Excellent, photographic quality | Limited by the number of screens/colors |

| Color Range | Full CMYK spectrum, millions of colors | Limited by number of screens/colors |

| Feel | Soft hand (especially on light fabrics) | Can be thick or plasticky, depending on ink/layers |

| Fabric Versa. | Best on cotton, cotton blends | Versatile across many fabric types |

| Eco-Friendly | Often water-based inks, less waste | Can use plastisol (less eco), more setup waste |

Key Benefits of DTG Printing

DTG printing offers distinct advantages for various stakeholders in the apparel industry, from burgeoning startups to established designers.

For Small Businesses

For startup entrepreneurs and small businesses in India, particularly those tapping into the vibrant pulse of Delhi’s streetwear scene, DTG is a powerful enabler:

- Lower Setup Costs: The initial investment required for Direct-to-Garment (DTG) printing is considerably less than that needed to establish a screen printing operation. DTG printing does not require extensive space for screens, drying racks, or multiple printing stations, making it an accessible option for small businesses.

- Quick Design Changes: Do you want to iterate on a design or release a new limited edition every week? Direct-to-Garment (DTG) printing allows for instant modifications without any material waste or the need for retooling.

- Ability to Produce On Demand: This is arguably the most significant game-changer. Businesses can adopt a true print-on-demand model in India, producing only what is ordered, thereby eliminating inventory risk and waste. This philosophy is central to platforms like PodLyft, which empower creators.

For Designers and Creatives

As I’ve advised numerous fashion designers, from Bengaluru’s tech-savvy creators to Mumbai’s avant-garde artists, DTG offers unparalleled creative freedom:

- Freedom to Print Complex Images: No more compromises on gradients, fine lines, or intricate details. Direct-to-Garment (DTG) printing enables designers to translate their vision onto fabric with remarkable fidelity.

- Cost-Effective for Prototypes and Limited Editions: Before a major launch, designers can print individual prototypes to test concepts without incurring significant setup costs. This approach is also ideal for creating exclusive, limited-run collections that command a higher value.

Industry Impact and Trends

The impact of Direct-to-Garment (DTG) printing on the textile industry, particularly in urban fashion trends, is undeniable. I have observed local custom apparel brands in cities such as Mumbai increase their sales by 30% or more within a year of transitioning to DTG. This growth is primarily attributed to their ability to offer unique, personalized designs and faster delivery compared to their competitors.

The impact of Direct-to-Garment (DTG) printing on the apparel industry is profound and continues to expand. According to GrandViewResearch, the global custom T-shirt market, a significant segment where DTG excels, was valued at $4.3 billion in 2023 and is projected to reach $7.5 billion by 2030, growing at a compound annual growth rate (CAGR) of 9.6%. At PodLyft, we have experienced a remarkable 40% increase in sales of personalized clothing over the past year, driven by the rising consumer demand for unique designs made possible through DTG technology, particularly in our custom T-shirt collection.

Explore Our Custom T-Shirt Collection

As an industry expert, I consistently observe how Direct-to-Garment (DTG) printing aligns with the broader movement towards personalization and sustainable production. The capability to print precisely what is needed, when it is needed, minimizes textile waste and overproduction—representing a significant advancement towards a more responsible fashion ecosystem.

How to Choose the Right DTG Printer

Choosing the best DTG printers for 2025 involves more than just selecting the right machine; it requires a clear understanding of your business volume and specific needs.

Key Features to Consider

When evaluating Direct-to-Garment (DTG) printers, consider the following essential features:

- Print Resolution (DPI): A higher DPI (dots per inch) results in sharper, more detailed prints. Look for machines that offer 1200 DPI or higher for photographic quality.

- Print Speed and Volume Capacity: How many garments can it print per hour? This information is crucial for managing order volumes. Be sure to consider your anticipated growth.

- Ink Quality and Color Range: Investigate the direct-to-garment (DTG) inks utilized. Are they from reputable manufacturers, durable, and do they provide a wide gamut of color options? The quality of white ink is particularly crucial.

Budget and Business Needs

When clients ask me, “Is DTG printing expensive to start?” I always explain that it is less about cost and more about investment—one that scales directly with your business goals.

Entry-Level vs. Professional-Grade Printers: The initial investment for Direct-to-Garment (DTG) printers varies significantly based on quality and production capacity. Entry-level models typically range from approximately ₹1.5 lakh to ₹12 lakh, making them relatively accessible for startups and small-scale operations. In contrast, industrial-grade machines designed for high-volume production can cost anywhere from ₹25 lakh to over ₹80 lakh. Your choice should be based entirely on your business scale, anticipated order volume, and your willingness to invest in long-term growth.

Maintenance Costs: This is an often-overlooked yet significant ongoing expense. In addition to the initial purchase price, you should also consider the following costs:

Ink is typically the largest ongoing expense, ranging from ₹40 to ₹200 per garment, depending on the complexity of the design and the color of the garment.

The cost of the pretreatment solution ranges from approximately ₹8 to ₹40 per garment.

Cleaning supplies and replacement parts are needed periodically to ensure your printer operates smoothly.

On average, annual maintenance costs can range from ₹40,000 to ₹1.2 lakh, depending on usage and the type of printer.

Support and Warranty Options: A robust warranty and dependable technical support are invaluable—especially for beginners. Effective post-sales support minimizes downtime, prevents costly repairs, and helps maintain consistent production schedules. In many cases, selecting a brand with superior warranty coverage and accessible support can save more money (and reduce stress) in the long run than opting for a less expensive machine without adequate backing.

Per-Shirt DTG Printing Cost Breakdown (Approx. in INR)

| Cost Type | Light Shirt (Approx. Cost) | Dark Shirt (Approx. Cost) |

|---|---|---|

| Ink | ₹41 – ₹83 | ₹124 – ₹208 |

| Pre-treatment Solution | ₹0 | ₹21 – ₹41 |

| Garment Blank (e.g., basic 100% cotton tee) | ₹124 – ₹332 | ₹124 – ₹332 |

| Maintenance (per shirt, amortized) | ~₹8 | ~₹8 |

| Electricity (per shirt, amortized) | ~₹4 | ~₹4 |

| Total Estimated Cost | ₹178 – ₹428 | ₹282 – ₹592 |

Real-world Tips

- Test with Sample Designs: Before making a significant investment, it is always advisable to request or conduct test prints on the specific target fabrics using actual designs. This approach provides a tangible assessment of print quality, color accuracy, and the final texture of the garment.

- Check Reviews from Other Users: Learning from the experiences of fellow entrepreneurs and businesses can provide invaluable insights. Online communities and industry forums frequently offer practical feedback on printer performance, reliability, and vendor support.

- Consider Training and Technical Support: While DTG printing is user-friendly, it does come with a learning curve. It is essential to ensure that operators receive comprehensive training and that the vendor offers robust post-sales support. Effective support can often be the key factor that distinguishes smooth operations from frustrating downtime.

The Future of DTG Printing in 2025

The future of Direct-to-Garment (DTG) printing is promising, characterized by continuous innovation and an expanding market.

Emerging Technologies

- Faster Printers with Higher Resolution: We are continually witnessing advancements that push the boundaries of speed while maintaining exceptional print quality. The new Direct-to-Garment (DTG) technology set to debut in 2025 will emphasize even faster processing and enhanced detail.

- Better, More Durable Inks: Ongoing research into eco-friendly direct-to-garment (DTG) inks aims to enhance wash fastness, color vibrancy, and versatility across a broader range of challenging fabrics, including polyester and blends.

- Integration with Automation Tools: The industry is increasingly adopting automated workflows, ranging from pre-treatment to curing, which streamline the direct-to-garment (DTG) printing process and minimize manual labor. These innovations in DTG printing will significantly enhance efficiency.

Market Predictions

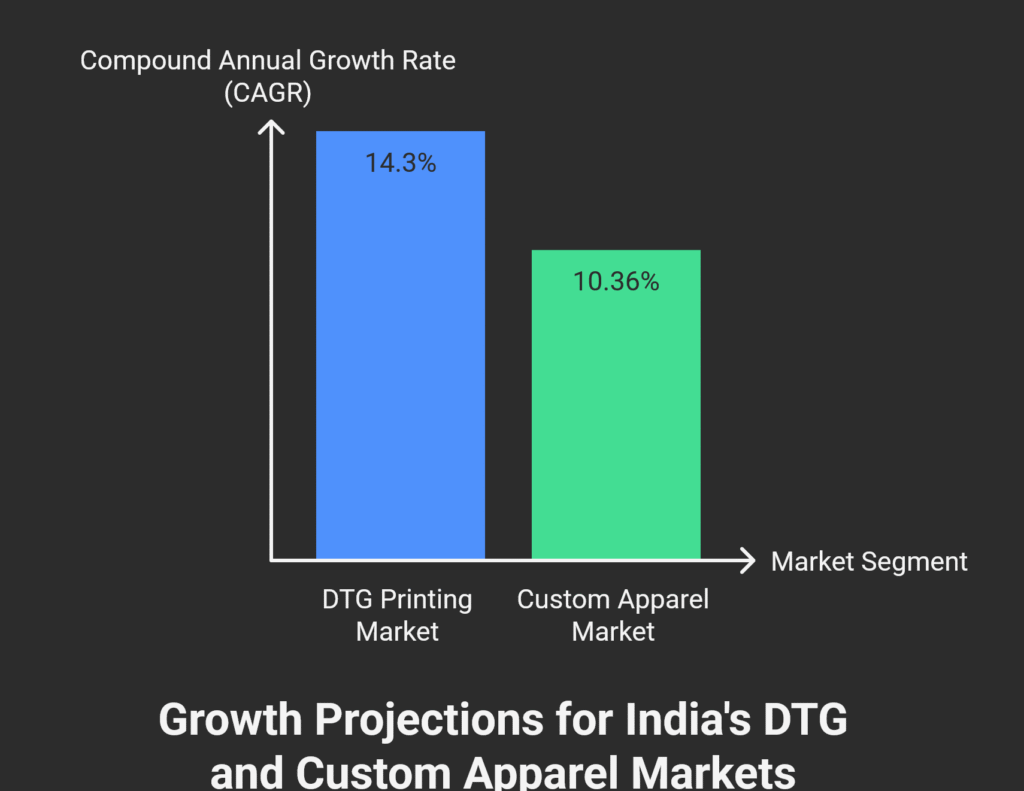

According to Grand View Research, India’s direct-to-garment (DTG) printing market is a powerhouse, anticipated to grow at a robust compound annual growth rate (CAGR) of 14.3% from 2025 to 2030, reaching USD 316.0 million by 2030. This growth significantly outpaces the global average, underscoring India’s unique position in this sector. Additionally, the broader Indian custom apparel market is thriving. According to a report published on GISuser, the Indian Custom Apparel Market is projected to grow from USD 48.83 million in 2024 to USD 107.46 million by 2032, at a CAGR of 10.36%.

This growth is fueled by several factors:

- Trends in Sustainable Inks: As environmental awareness increases, the demand for eco-friendly direct-to-garment (DTG) inks and sustainable production methods will continue to rise.

- Growing Demand in Niche Markets: From personalized sports team jerseys to hyper-local streetwear brands, direct-to-garment (DTG) printing is ideally positioned to meet the needs of niche markets that require customization and rapid turnaround times. This trend is especially evident in the custom apparel sector in India, where brands are increasingly focusing on specific subcultures.

India DTG & Custom Apparel Market Projections (2024-2032)

| Market Segment | 2024 Value (USD Million) | 2025 Value (USD Million) | Projected 2030/2032 Value (USD Million) | CAGR (2025-2030/2032) |

| Global DTG Printing Market | $847.3 | $873.5 | $1,343.6 (by 2035) | 4.4% (2025-2035) |

| India DTG Printing Market | $144.9 | (N/A) | $316.0 (by 2030) | 14.3% (2025-2030) |

| India Digital Textile Printing Market (DTG Segment) | $466.7 (total digital textile) | (N/A) | $1,134.0 (by 2030) | 16.4% (2025-2030) |

| India Custom Apparel Market | $48.83 | (N/A) | $107.46 (by 2032) | 10.36% (2024-2032) |

Actionable Takeaways

Invest Early in Quality Equipment: The long-term advantages of reliable and efficient Direct-to-Garment (DTG) printers, such as consistent output and minimized downtime, significantly surpass the initial savings associated with cheaper, less capable machines.

Stay updated on Ink Formulations: Ink technology is constantly evolving. Staying informed about new, more durable, and increasingly eco-friendly options will provide a significant competitive advantage in a market that values both quality and sustainability.

Explore Niche Markets for Growth: Businesses should look beyond generic custom t-shirts. By identifying specific urban fashion trends or communities, such as local music scenes, gaming communities, and corporate branding opportunities in Bangalore’s tech hubs, that place a high value on personalized apparel, companies can create tailored offerings and achieve deeper market penetration.

Conclusion

From my perspective, having witnessed the evolution of the textile industry and the flourishing of the custom apparel movement, direct-to-garment (DTG) printing emerges as a transformative technology. Its capacity to produce high-quality, full-color prints on demand with relatively low setup costs makes it an exceptionally powerful tool for small to medium-sized businesses and individual creators alike.

As we enter 2025, several trends have emerged: personalization reigns supreme, sustainability is imperative, and speed to market is crucial. Direct-to-garment (DTG) printing effectively meets these demands, providing an agile, efficient, and creatively liberating solution for anyone aiming to make an impact in the apparel industry. It transcends traditional printing methods; it serves as a bridge between creativity and commerce, enabling unique visions to be realized on fabric. If you are serious about launching or expanding your custom apparel business, exploring DTG printing options is not merely advisable—it is essential for future growth and success.

DTG Printing FAQs

DTG (Direct-to-Garment) printing is a digital printing method that sprays water-based inks directly onto fabric, much like an inkjet printer on paper. It allows for full-color, high-detail designs without the need for screens or setup costs.

DTG printing emerged in the early 2000s as a response to the demand for on-demand, full-color garment decoration.

DTG requires no screens, making it ideal for small runs and detailed designs. Screen printing is better for bulk orders with limited colors.

Yes, DTG uses water-based inks that are free from harmful chemicals like PVC and phthalates, and it minimizes textile waste by printing on demand.

100% cotton or cotton-rich blends are ideal as they absorb ink better and deliver vibrant prints.

It can, but colors may appear less vibrant. Pre-treatment and special inks can improve results on blends.

Modern DTG prints are highly durable if properly cured and cared for, but screen prints may still outperform DTG for extreme long-term wear.

Medium-weight fabrics between 150–250 GSM work best for DTG as they provide a stable surface for high-quality prints.

No, DTG has a soft hand feel since the ink absorbs into the fibers, unlike thick plastisol layers in screen printing.

High-resolution PNG files with a transparent background are best for DTG. Vector files like AI or EPS can also be used.

It’s an investment that scales with ambition. Entry-level DTG printers cost ₹1.5–₹12 lakh, while industrial machines can exceed ₹80 lakh.

Dark shirts cost more due to the white ink underbase and pre-treatment needed, roughly ₹50–₹100 extra per shirt compared to light garments.

On average, light shirts cost ₹180–₹430 per print, while dark shirts range from ₹280–₹600 depending on ink coverage and fabric quality.

Screen printing is cheaper for large volumes, while DTG is better for low-volume, highly detailed designs.

Yes! It’s ideal for print-on-demand businesses since you can print only what’s ordered, reducing inventory risk.

Maintenance can cost ₹40,000–₹1.2 lakh annually, including cleaning solutions, replacement parts, and routine servicing.

It varies by design, but a standard A4 print uses ₹40–₹150 worth of ink.

Entry-level models cost ₹1.5–₹12 lakh, while industrial-grade printers can range from ₹25 lakh to over ₹80 lakh.

Lower setup costs, no minimum order quantity, quick turnaround for small runs, and the ability to print complex designs.

Absolutely! DTG excels at full-color, gradient-rich, and photographic prints.

Because it allows true on-demand printing without pre-production, making it perfect for customized apparel.

It’s slower for bulk orders, works best on cotton fabrics, and has higher ink costs than screen printing.

For 1–50 pieces, DTG is ideal. For 500+ pieces, screen printing is more cost-effective.

Most are water-based, biodegradable, and free from toxic chemicals, making them safer for both workers and the environment.

Pre-treatment helps white ink adhere properly on dark garments, ensuring vibrant colors and sharp details.

Yes, they require pre-treatment and a white underbase before printing the full-color design.

A single print usually takes 2–5 minutes, depending on design size and printer speed.

After printing, the shirt is heat-pressed or conveyor-cured to bond the ink with the fabric, improving wash durability.

300 DPI is the industry standard for sharp, high-quality prints.

Common mistakes include insufficient pre-treatment, incorrect curing, and low-resolution files. Proper training and calibration prevent these issues.

Yes, it aligns with trends like personalization, sustainable production, and on-demand fulfillment.

The global DTG market is projected to exceed $4 billion by 2025 with double-digit annual growth.

Consumers crave unique, one-of-a-kind apparel that reflects their identity, making DTG perfect for this demand.

It reduces overproduction and textile waste by enabling just-in-time manufacturing.

Faster printers, better eco-friendly inks, and increased automation in pre-treatment and curing.

India’s DTG market is projected to grow at a 14% CAGR, with custom apparel hitting ₹890 crore by 2032.

DTG is better for small runs with detailed designs, while screen printing is better for bulk, simple designs.

Sublimation is great for polyester fabrics, while DTG is ideal for cotton and blended fabrics with high detail.

Not entirely. DTG complements rather than replaces screen and sublimation printing, each having its niche.

DTF is more versatile for fabrics but DTG offers softer prints and higher color detail.

Use high-quality cotton garments, proper pre-treatment, high-resolution files, and correct curing temperatures.

Wash inside out in cold water, avoid bleach, and tumble dry on low heat to extend print life.

Consider your budget, expected order volume, support availability, and print quality.

Brands like Epson, Brother, Kornit, and Ricoh dominate the DTG market with reliable machines.

Print a small sample to check color vibrancy, wash fastness, and garment shrinkage.

Optimize ink usage, use efficient RIP software, and source blank garments at wholesale rates.