- No products in the cart.

Key Takeaways

- Market Opportunity:

- India’s custom apparel market is growing at a compound annual growth rate (CAGR) of 10.36%, significantly outpacing the overall apparel market’s growth rate of 4%.

- The custom t-shirt printing segment is expected to reach ₹385.8 million by 2033, growing 2.5 times faster than the traditional apparel market.

- Urban consumers increasingly prefer personalized fashion to mass-produced alternatives.

- Technology and Investment:

- DTF printing has emerged as the ideal solution for Indian entrepreneurs—it works on all fabric types and is cost-effective for runs of 25 to 500 pieces.

- Entry-level businesses can start with an investment of ₹1-3 lakhs (HTV setup), while commercial operations typically require an investment of over ₹20 lakhs.

- DTG excels in cotton-based, small-batch premium orders, while screen printing remains the preferred method for large volumes.

- Business Economics:

- Profitable pricing structure: 35-45% material costs, 20-30% printing costs, and 20-30% profit margins achievable.

- The print-on-demand hybrid model (70% POD, 30% inventory) optimizes cash flow and product variety.

- Regional positioning in tier-2 cities such as Pune and Indore offers competitive advantages.

- Cultural Drivers:

- The creator economy and micro-influencers are driving 60% of the demand for custom merchandise.

- Regional pride and local language designs are creating niche opportunities.

- Gen Z’s Preference for Identity-Based Fashion Is Reshaping Consumer Behavior

- Success Factors:

- Quality focus—using 160-180 GSM fabrics and proper curing—is essential for customer retention.

- A quick turnaround time of 24 to 48 hours is becoming a key competitive differentiator.

- Matching the fabric print method is crucial for achieving optimal results and durability.

- Future Trends:

- AI-assisted design generation reduces production time.

- Sustainability Practices Commanding Premium Pricing

- Local streetwear brands are challenging international giants by leveraging cultural relevance.

Introduction

India’s Custom Apparel landscape is undergoing a quiet revolution. Walking through Mumbai’s Bandra West or Delhi’s Hauz Khas Village today, you’ll notice something striking: nearly every third person is wearing something uniquely their own: a band tee from a local indie artist, a hoodie featuring a clever Hindi-English mashup quote, or a custom jersey celebrating their favorite cricket team. This is no coincidence; it is the visible manifestation of India’s custom apparel revolution.

After spending more than a decade navigating fabric mills in Tirupur, consulting with fashion startups from Bangalore’s tech corridors to Mumbai’s creative hubs, and observing countless entrepreneurs transform their design dreams into profitable ventures, I have witnessed firsthand how custom printing has evolved from a niche service into the backbone of India’s next apparel boom.

If you are a designer, an aspiring entrepreneur, or simply someone who wants to wear a shirt that truly reflects your identity, this guide will provide you with practical knowledge to navigate the market, choose the right printing method, and launch a profitable custom apparel venture.

Why Custom Apparel is Exploding Across Indian Markets

The pulse of Indian fashion beats to a distinct rhythm today. Gone are the days when consumers were content with generic designs. The burgeoning middle class, combined with the explosion of social media and the creator economy, has fueled an insatiable demand for unique, identity-driven fashion. I have witnessed firsthand how streetwear printing in India has expanded from niche markets, such as T-shirt printing in Mumbai and custom apparel printing in Delhi, into mainstream consciousness.

The Numbers Tell the Story

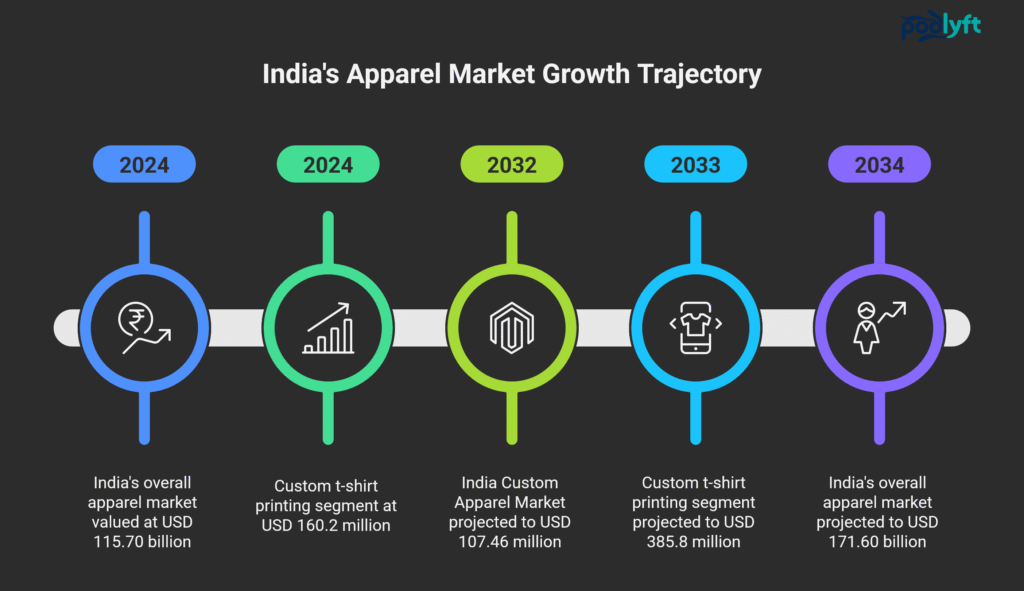

The growth trajectory speaks for itself. India’s overall apparel market, valued at USD 115.70 billion in 2024, is projected to reach USD 171.60 billion by 2034—a steady 4% CAGR that reflects the sector’s fundamental strength, according to Market Research Future.

But here’s where it gets interesting: while the broader apparel market grows at 4%, the custom apparel segment is absolutely surging. The India Custom Apparel Market is racing ahead at a 10.36% CAGR, projected to more than double from USD 48.83 million in 2024 to USD 107.46 million by 2032, as reported by Credence Research.

Even more striking is the custom t-shirt printing segment—the entry point for most entrepreneurs I’ve guided. This niche exploded to USD 160.2 million in 2024 and is expected to reach USD 385.8 million by 2033, growing at 10.26% annually, according to IMARC Group’s analysis. That’s nearly 2.5x faster than the overall apparel market.

Having worked with startups capturing pieces of this growth, I can confirm these numbers align with ground reality. The entrepreneurs who positioned themselves early in tier-2 cities like Pune, Indore, and Coimbatore are now seeing the benefits of this market expansion firsthand.

The Personalization Shift

The mass-produced, uniform look that dominated Indian fashion for decades is rapidly losing ground. Today’s consumers, especially in urban centers such as Pune, Hyderabad, and Chennai, are not just purchasing clothes—they are buying identity.

This shift became crystal clear during my recent visit to a screen printing workshop in Koramangala, Bangalore. The owner, Rajesh, showed me orders ranging from 50-piece runs for local gaming cafes to single custom hoodies for college students. “Five years ago, minimum orders were 500 pieces,” he explained. “Now, we’re profitable printing just 10 shirts with the right pricing strategy.”

Key Market Drivers:

- Creator Economy Boom: With over 100 million content creators in India, personal branding through custom apparel has become essential.

- Regional Pride: Increasing demand for local language designs, city-specific graphics, and cultural references

- Quality Consciousness: Urban consumers are increasingly preferring well-crafted custom pieces over fast fashion alternatives.

- Gift Culture Evolution: Personalized apparel has become the preferred choice for corporate gifts and special occasions.

Cultural Trends Reshaping Fashion

The rise of Indian streetwear culture has been remarkable. Walking through Delhi’s Connaught Place or Mumbai’s Linking Road, you will notice how local brands like Koovs and Bewakoof have popularized graphic tees and custom designs. However, the real momentum is building at the grassroots level.

In Bangalore’s tech parks, I have observed teams creating custom hoodies for hackathons. In Mumbai, members of the film industry commission personalized crew jackets. Even traditional festival celebrations now feature custom-printed ethnic wear incorporating modern graphic elements.

Key Printing Methods Explained: The Technology Behind the Boom

Navigating the world of apparel printing technology can be overwhelming, but understanding the core methods is essential for ensuring both quality and cost-effectiveness. In my experience, each technique offers unique advantages and is suited to specific applications.

Here’s a breakdown of the most popular apparel printing styles in India:

DTG (Direct-to-Garment) Printing India: This technology is akin to an inkjet printer for fabric. It sprays ink directly onto the garment, allowing for incredibly detailed, full-color designs with gradients and photographic quality.

- Pros: High detail, vibrant colors, soft feel (ink dyes the fabric), no setup costs per design, ideal for low quantity and on-demand printing.

- Cons: Best on cotton, can be slower for bulk orders, higher ink costs, white ink can be tricky on dark garments.

Investment Range: ₹8-25 lakhs for professional setups

Screen Printing Services India: This is the veteran of apparel printing, known for its vibrant colors and durability. Ink is pushed through a mesh screen onto the fabric using a stencil for each color.

- Pros: Economical for large quantities, extremely durable prints, vivid colors, and works on various fabrics.

- Cons: High setup costs (screens for each color), limited color palette per design, not ideal for intricate details or gradients, longer turnaround for small runs.

Setup Costs: ₹50,000-3 lakhs, depending on automation level

DTF (Direct-to-Film) Printing: A newer entrant, DTF prints a design onto a special film, which is then transferred to the fabric using heat and pressure. It’s quickly gaining traction for its versatility.

- Pros: Works on almost any fabric type (cotton, poly, blends), vibrant colors, good detail, excellent durability, no pre-treatment needed for many fabrics.

- Cons: Can have a slightly thicker feel than DTG, precise application is required, specialized powder, and curing process.

Setup Costs: ₹76,488 – ₹2,70,000 or more.

Heat Transfer Vinyl (HTV) Printing: Designs are cut from rolls of colored vinyl and then heat-pressed onto the garment.

- Pros: Great for names, numbers, simple logos, specific textures (glitter, flock), and durability.

- Cons: Limited detail, blocky feel, not ideal for complex graphics or large areas.

Setup Costs: approximately ₹30,000 to over ₹3,80,000

Sublimation Printing India: Ink turns into a gas when heated and permanently dyes polyester fabric.

- Pros: Permanent, lightweight, vibrant, all-over printing capabilities, breathable.

- Cons: Only works on light-colored polyester fabrics; not suitable for cotton.

Setup Costs: ₹8,500 – ₹2,45,000+

Here’s a quick comparison:

| Method | Best For | Pros | Cons | Typical Use Cases |

|---|---|---|---|---|

| DTG Printing | Fine detail, full-color, low runs | High detail, no setup costs (per print), soft feel, excellent for photos | Slower for bulk, fabric limitations (best on cotton), higher ink cost | Slightly thicker feel (though improving), specialized equipment, and process |

| Screen Printing | Bulk orders, vibrant colors, durability | Economical for large runs, highly durable, vibrant colors | “Custom graphic tees India”, intricate designs, and photographic prints | “Bulk t-shirt printing India”, team apparel, simple logos, large events |

| DTF Printing | Versatility across fabrics, vibrant, durable | Good detail, works on many fabrics, durable, vibrant | Slightly thicker feel (though improving), specialized equipment and process | “Streetwear printing India”, intricate designs on diverse fabrics, promotional wear |

| Heat Transfer Vinyl | Small runs, specific effects, numbers | Durable, versatile for specific effects (gloss, flock), easy for names/numbers | Not ideal for complex, multi-color designs; can feel thick; limited colors per vinyl | “Personalized hoodies India”, sports jerseys, single-color logos |

| Sublimation Printing | Polyester, all-over prints, vibrant | Permanent, lightweight, vibrant, breathable | Only on light-colored polyester or poly-coated items; not for cotton; limited dark fabric options | High setup costs (screens), limited colors per design, and less detail |

Starting Your Custom Apparel Business in India

Embarking on a custom t-shirt printing business plan in India requires more than just a passion for fashion; it demands strategic planning. My journey has taught me that the foundation you lay at the outset determines your growth potential.

- Legal Structure & Registration: Start by registering your business. A proprietorship is simplest initially, but consider a Private Limited Company for better funding prospects and liability protection as you grow. Secure your GSTIN and other necessary local permits.

- Sourcing Blank Apparel India: This is critical. Quality blanks are the canvas for your art. I always advise entrepreneurs to meticulously vet suppliers for cotton, poly-cotton blends, and polyester. Look for consistency in GSM (grams per square meter), stitching, and color fastness. Many domestic manufacturers offer competitive pricing for bulk t-shirt printing in India.

- Choosing Your Printing Method: Based on your target audience, design complexity, and budget, decide which technology to invest in or outsource. For unique, low-volume designs, DTG or DTF might be ideal. For larger corporate orders or event t-shirt printing, screen printing services in India would be more cost-effective.

- Cost to Start: The investment varies significantly:

- Lean Startup (Outsourcing): You can begin with ₹20,000 – ₹50,000 by designing and marketing, then fulfilling orders through external custom print shop India services. This is great for testing the waters.

- Mid-Tier (HTV/Small DTF): Investing in a heat press and a vinyl cutter or a small DTF setup might cost ₹1.5 – ₹5 lakhs. This allows for in-house production of specific product categories like personalized hoodies in India.

- Professional Setup (DTG/Screen Printing): A commercial DTG machine can range from ₹5 lakhs to ₹50 lakhs+, while a full screen printing setup might be ₹2 lakhs to ₹10 lakhs, depending on automation. This scale is for serious players aiming for significant volume and diverse offerings.

Primary Sourcing Hubs:

- Tirupur, Tamil Nadu: Cotton t-shirts, competitive pricing

- Bangalore, Karnataka: Quality blanks, tech-friendly logistics

- Mumbai, Maharashtra: Fashion-forward styles, quick turnaround

- Delhi NCR: Comprehensive variety, strong distribution network

Fabric Selection Tips:

- 160-180 GSM cotton for premium feel

- 50/50 cotton-polyester blends for durability

- 100% cotton for DTG printing

- Ring-spun cotton for superior print quality

Choosing the Right Printing Tech for Your Brand

| Method | Initial Investment | Per-Piece Cost | Best Volume | Fabric Types | Setup Time |

| DTG | High (₹8-25L) | ₹45-80 | 1-50 | Cotton/Blends | Medium |

| Screen Print | Medium (₹50K-3L) | ₹15-35 | 100+ | Most fabrics | High |

| DTF | Medium (₹3-8L) | ₹25-50 | 25-500 | All types | Low |

| HTV | Low (₹15K-1L) | ₹35-65 | 1-25 | Most fabrics | Very Low |

| Sublimation | Medium (₹2-6L) | ₹20-45 | 50+ | Polyester only | Medium |

Economics of Custom Apparel Printing: Maximizing Profitability

Pricing your custom prints in India can feel like walking a tightrope. You need to remain competitive while ensuring healthy profit margins. My advice? Don’t focus solely on the raw production cost.

Pricing Strategy Framework

Through analyzing successful operations from Chennai to Chandigarh, I’ve developed a pricing framework that ensures profitability while remaining competitive:

Cost Components:

- Blank apparel: 35-45% of the selling price

- Printing costs: 20-30%

- Design and setup: 10-15%

- Marketing and operations: 15-20%

- Profit margin: 20-30%

Profit Margins by Method

DTG Printing:

- Single piece: ₹150-300 profit

- Bulk orders (25+): ₹80-150 profit per piece

Screen Printing:

- Small runs (100-500): ₹25-45 profit

- Large runs (1000+): ₹15-30 profit

DTF Printing:

- Medium runs (50-200): ₹45-75 profit

- High-detail designs: ₹60-100 profit

Inventory vs Print-on-Demand

This is a crucial strategic decision. Holding inventory (the traditional model) can reduce per-unit costs but involves storage risks and requires significant upfront capital. Print-on-demand (PoD) reduces these risks by allowing you to offer a vast catalog without investing in stock. Many successful brands, such as PodLyft, leverage POD models to scale efficiently and respond quickly to the latest custom t-shirt trends in India without the burden of heavy inventory. They have developed the systems and credibility that enable entrepreneurs to focus on design and marketing, effectively becoming key custom apparel suppliers in India through their service.

Hybrid Approach Benefits:

- 70% print-on-demand for variety

- 30% inventory for fast-moving items

- Reduced storage costs

- Improved cash flow management

Fabric Science: The Foundation of Quality Printing

This is where my textile background truly comes into play. You can have the best apparel printing technology in India, but if you pair it with the wrong fabric, your prints will suffer.

- Fabric Types:

- 100% Cotton: The gold standard for DTG printing due to its natural fibers absorbing ink beautifully, resulting in soft, vibrant prints. It’s also excellent for screen printing.

- Poly-Cotton Blends: Good for screen printing. For DTG, results can vary; pre-treatment is often crucial.

- 100% Polyester: Essential for sublimation printing. For DTF, it works incredibly well, offering bright, durable prints. Screen printing on polyester also works, but requires specialized inks.

- GSM (Grams per Square Meter): This dictates the fabric’s weight and density. For DTG and DTF printing, I generally recommend blanks with a GSM of 180-220 for t-shirts. Lower GSM can lead to ink bleed-through or a flimsy feel. Higher GSM (e.g., for personalized hoodies) provides a richer, more substantial base.

- Matching Printing Technique to Fabric: Always consider how the ink will interact with the fabric. A print that looks stunning on a 100% cotton tee via DTG might look dull or crack on a polyester blend. My rule of thumb: Test, test, test!

Trends Driving the Industry in 2025 and Beyond

The custom apparel industry in India is dynamic and continuously evolving, driven by changes in consumer behavior and technological advancements.

Gen Z and the Creator Economy

The creator economy has fundamentally transformed demand patterns for custom apparel. YouTubers in Mumbai, gaming streamers in Bangalore, and fashion influencers in Delhi are driving unprecedented demand for personalized merchandise.

Key Observations:

- Micro-influencers (10K-100K followers) represent 60% of custom merch demand

- Average order size: 25-75 pieces

- Preference for unique, limited-edition designs

- Strong emphasis on quality over quantity

AI-Assisted Fashion and Personalization

Artificial intelligence is streamlining design processes and enabling mass personalization. I have observed Pune-based startups using AI to generate custom designs based on customer preferences, reducing design time from hours to minutes.

Emerging Applications:

- Automated design generation

- Color palette optimization for different skin tones

- Predictive inventory management

- Dynamic pricing based on demand patterns

Rise of Regional Streetwear Brands

Local streetwear brands are challenging international giants by offering culturally relevant designs and superior customization options. From Mumbai’s hip-hop scene to Bangalore’s tech culture, these regional brands are carving out distinct niches.

Sustainability as a Competitive Advantage

Sustainable Practices:

- Water-based inks for screen printing

- Organic cotton blanks

- Local sourcing to reduce the carbon footprint

- Minimal packaging approaches

Real Story from the Ground: Delhi’s Custom Success

Last year, I consulted with Arjun, a 26-year-old entrepreneur who started his custom apparel business in Lajpat Nagar, Delhi. Beginning with a modest ₹2 lakh investment in DTF printing, he focused exclusively on college merchandise and local band merchandise.

Initial Challenges

- Quality Control: Early prints showed poor wash durability

- Pricing Pressure: Competing with established screen printers

- Seasonal Fluctuations: Heavy dependence on college event cycles

Strategic Solutions

Quality Improvement: Invested in premium DTF films and proper curing equipment, resulting in prints lasting 50+ washes.

Niche Positioning: Specializing in quick turnaround custom orders (24-48 hours) for time-sensitive events.

Revenue Diversification: Expanded into corporate merchandise and online sales through Instagram and local marketplaces.

Results After 18 Months

- Monthly revenue: ₹8-12 lakhs

- Profit margins: 35-40%

- Customer base: 200+ repeat clients

- Expansion plans: Adding DTG capability for photo-realistic prints

Your Custom Apparel Launch Checklist

Phase 1: Foundation (Weeks 1-4)

- Complete market research in your target area

- Finalize business registration and licenses

- Secure initial funding and workspace

- Research and contact blank apparel suppliers

Phase 2: Setup (Weeks 5-8)

- Purchase and install printing equipment

- Establish supplier relationships

- Develop a pricing strategy

- Create a sample portfolio

Phase 3: Launch (Weeks 9-12)

- Soft launch with friends and local network

- Gather feedback and refine processes

- Launch digital marketing campaigns

- Establish customer service workflows

Essential Tools and Software

Design Software:

- Adobe Illustrator (industry standard)

- Canva Pro (user-friendly alternative)

- CorelDRAW (popular in Indian markets)

RIP Software for Printing:

- Epson Edge Print (for Epson DTG printers)

- AcroRIP (versatile and cost-effective)

- Wasatch SoftRIP (professional-grade)

Business Management:

- Tally for accounting

- WhatsApp Business for customer communication

- Instagram for marketing and sales

The Future Landscape: What’s Coming Next

The custom apparel industry in India is at a pivotal moment. The convergence of technology, evolving consumer behaviors, and entrepreneurial innovation is generating unprecedented opportunities.

Emerging Opportunities:

- Integration of augmented reality for virtual try-ons

- Blockchain-based authenticity certificates for limited editions

- Subscription models for personalized apparel

- Cross-border e-commerce for Indian designs globally

Challenges to Navigate:

- Rising raw material costs

- Skilled labor shortages in tier-2 cities

- Increasing competition from established players

- Regulatory changes affecting small businesses

Conclusion: Seizing the Custom Apparel Moment

The transformation of India’s apparel industry from mass production to mass customization represents more than just a business opportunity—it signifies a cultural shift toward individual expression and entrepreneurial empowerment.

From the bustling printing workshops of Mumbai to the tech-enabled startups of Bangalore, and from the traditional textile hubs of Tamil Nadu to the emerging fashion centers of Pune and Kolkata, custom printing is democratizing fashion entrepreneurship like never before.

The convergence of accessible technology, increasing consumer awareness, and supportive digital infrastructure has created ideal conditions for the next wave of fashion entrepreneurs. Whether you are a college student passionate about design, a corporate professional seeking a side venture, or an experienced businessperson looking to diversify, the custom apparel industry offers scalable opportunities at every investment level.

The question is not whether custom printing will continue to grow in India, but whether you will be part of shaping this transformation. The tools are accessible, the market is receptive, and the timing could not be better.

The future of Indian fashion is personal, being crafted one custom piece at a time.