- No products in the cart.

Print-on-Demand Startup in India doesn’t have to cost a fortune, but it does require a smart plan. Last week, I met with Priya, a graphic designer from Pune who had been sketching streetwear designs for months but felt overwhelmed by the financial commitment of launching her apparel brand. “I don’t have lakhs to invest like traditional fashion brands,” she said, “but I can’t shake the feeling that my designs deserve to be worn.”

This conversation occurs more often than you might think. The good news? Print-on-demand has democratized fashion entrepreneurship in India, enabling creative individuals to launch profitable apparel brands with surprisingly modest investments. After assisting dozens of entrepreneurs in navigating POD startup costs across various Indian cities, I can confidently say that smart planning consistently outperforms large budgets.

This cost breakdown forms an essential part of our complete guide to custom apparel printing in India, providing you with realistic financial expectations and strategic investment priorities for 2025.

Why POD Is India’s Smartest Low-Investment Apparel Model

When I first started consulting fashion entrepreneurs five years ago, the biggest barrier wasn’t creativity—it was capital. Traditional apparel businesses demanded ₹15-50 lakhs just for initial inventory, leaving countless talented designers watching from the sidelines. Print-on-demand has completely transformed this landscape.

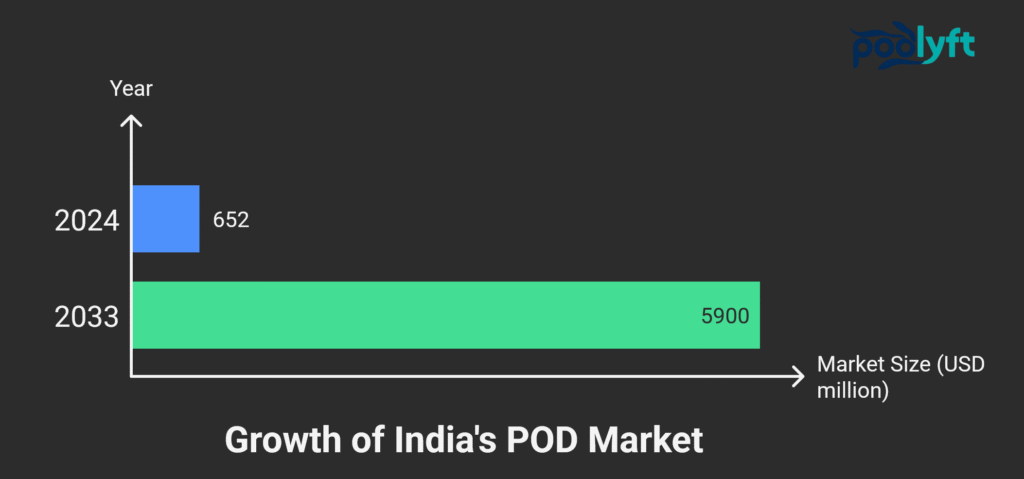

The numbers tell a compelling story. India’s POD market reached USD 652 million in 2024 and is projected to explode to USD 5.9 billion by 2033, a staggering 27.8% CAGR that reflects genuine market demand rather than speculative growth. Having worked with startups that began with just ₹30,000 and now generate monthly revenues exceeding ₹2 lakhs, I can confirm these projections align with ground reality.

What makes POD particularly powerful in India is our expanding middle class, expected to surpass 200 million by 2025. These consumers aren’t just buying clothes, they’re buying identity, personalization, and stories that resonate with their values. During my recent consultation with a Bangalore-based creator targeting regional humor designs, we discovered his Tamil comedy tees were selling 300% better than generic designs, proving that cultural specificity drives premium pricing.

The operational advantages are equally impressive. No inventory nightmares, no seasonal write-offs, no cash tied up in unsold stock. You print only what’s already sold, test designs with minimal financial risk, and pivot based on actual customer response rather than gut feelings. This model has enabled creators I’ve mentored to validate 15-20 different design concepts simultaneously, something impossible with traditional manufacturing minimums.

Minimal Inventory Risk Revolution:

Traditional fashion retail requires a substantial upfront investment in inventory, often ₹5 to 15 lakhs just for the initial stock. While consulting for a Mumbai-based fashion startup, I witnessed them nearly go bankrupt when 70% of their first collection failed to sell. Print-on-demand eliminates this risk.

With print-on-demand (POD), you print only after receiving orders. This eliminates dead inventory, seasonal write-offs, and cash flow problems caused by unsold stock gathering dust in warehouses.

Complete Design Control:

Unlike dropshipping or wholesale models, print-on-demand (POD) gives you full creative control over your brand’s visual identity. You’re not competing with hundreds of other sellers offering the same products—you’re building a unique brand centered around your original designs.

Perfect for Niche Markets:

India’s diverse cultural landscape offers countless niche opportunities. Whether it’s regional humor T-shirts in Tamil, Bengali literature-inspired designs, or cricket commentary memes, print-on-demand (POD) enables you to serve specific communities profitably without requiring large order quantities.

Space-Efficient Operations:

Most successful POD operations I’ve consulted run out of spare bedrooms, converted garages, or small rented spaces. One Delhi-based creator I worked with generated ₹8 lakhs in annual revenue from a 10×12-foot room in Lajpat Nagar.

Complete Initial Print-on-Demand Startup Setup Cost Breakdown (2025)

The complete initial setup cost breakdown for a print-on-demand (POD) business in 2025 includes essential investments such as printing equipment, heat press machines, design software, website and e-commerce setup, and initial raw material inventory. Starting with a quality DTF printer priced between ₹2.5 and 4 lakh, along with an entry-level heat press, provides a versatile and cost-effective foundation. This setup is supported by affordable design tools and a well-planned digital storefront. Strategic selection of fabric and inventory further optimizes print quality and cash flow for new POD entrepreneurs.

1. Printing Equipment Investment

The core of your POD operation lies in selecting the right printing technology. This is based on current market prices across India.

| Monthly Capacity | Cost Range | Best For | Monthly Capacity |

| Entry-level DTF | ₹1.5 – ₹4 lakh | New creators, testing designs | 200-500 pieces |

| Professional DTF | ₹4 – ₹8 lakh | Growing POD brands | 500-1200 pieces |

| Entry-level DTG | ₹8 – ₹14 lakh | Premium cotton prints | 300-800 pieces |

| Professional DTG | ₹14 – ₹25 lakh | High-volume operations | 1000+ pieces |

My Recommendation for Beginners: Start with a quality DTF system in the ₹2.5-4 lakh range. It offers versatility across fabric types and excellent print quality for most POD applications.

2. Heat Press Machine

Essential for applying DTF transfers and finishing prints:

- Basic Heat Press (15″x15″): ₹15,000 – ₹25,000

- Professional Heat Press (16″x20″): ₹25,000 – ₹45,000

- Pneumatic Press (for high volume): ₹45,000 – ₹80,000

Smart Choice: Invest in a reliable 15″x 15″ press initially. Most POD designs fit comfortably within this size, and you can upgrade later as volume grows.

3. Design Software Essentials

Your creative toolkit determines design quality and efficiency:

| Software | Cost | Best For |

| Canva Pro | ₹3,999/year | Beginners, social media graphics |

| Adobe Creative Suite | ₹36,000/year | Professional designs, complex artwork |

| CorelDRAW | ₹25,000 one-time | Vector graphics, popular in India |

| GIMP | Free | Budget-conscious creators |

Pro Tip: Start with Canva Pro for your first 6 months. It’s user-friendly and includes commercial licenses for design elements. Upgrade to Adobe once you’re generating consistent revenue.

4. Website and E-commerce Setup

Your digital storefront requires strategic investment:

| Component | Cost Estimate | Notes |

| Domain & Hosting | ₹2,500 – ₹6,000/year | Choose reliable hosting |

| WooCommerce Setup | Free | Choose a reliable hosting |

| Premium Theme | ₹3,000 – ₹8,000 | Professional appearance |

| Essential Plugins | ₹5,000 – ₹12,000/year | Payment, SEO, analytics |

| SSL Certificate | ₹1,500 – ₹3,000/year (or free) | Trust and security |

Total Website Investment: ₹12,000 – ₹29,000 for the first year

5. Initial Raw Material Inventory

Strategic inventory planning optimizes cash flow:

Basic Starter Pack (₹10,000-15,000):

- 20-30 white cotton tees (160 GSM)

- 10-15 black cotton tees

- 10-15 navy or other popular colors

- 5-10 hoodies for testing

Fabric Selection Strategy: Focus on 100% cotton for DTG compatibility, or cotton-poly blends for DTF versatility. Understanding fabric GSM helps optimize print quality and cost.

Hidden Ongoing Costs Every POD Entrepreneur Must Know

Hidden ongoing costs that every Print-On-Demand (POD) entrepreneur must consider include per-print variable expenses such as materials, ink, electricity, and labor, which range from ₹28 to ₹53 per piece for DTF printing and ₹36 to ₹67 for DTG printing. Additionally, budgeting for equipment maintenance, approximately ₹25,000 to ₹60,000 annually for DTF systems and up to ₹1.2 lakh for DTG, is crucial to prevent costly downtime. Shipping and fulfillment also impact profitability, with local delivery costing ₹30 to ₹50 per order and packaging adding ₹8 to ₹15. However, negotiating bulk courier rates can save 20 to 30% once order volumes increase. These costs significantly affect profit margins and require careful management to ensure sustainable growth.

Per-Print Variable Costs

These costs directly impact your profit margins:

DTF Printing Costs per Piece:

- Transfer film and powder: ₹12-18

- Ink consumption: ₹8-15

- Electricity (printing + heat press): ₹3-8

- Labor time: ₹5-12

- Total per print: ₹28-53

DTG Printing Costs per Piece:

- Pre-treatment (dark shirts): ₹8-12

- Ink consumption: ₹15-30

- Electricity: ₹5-10

- Labor time: ₹8-15

- Total per print: ₹36-67

Equipment Maintenance Budget

Plan for ongoing maintenance to avoid costly breakdowns:

- DTF System Maintenance: ₹25,000-60,000/year

- DTG System Maintenance: ₹40,000-1.2 lakh/year

- Heat Press Servicing: ₹3,000-8,000/year

Shipping and Fulfillment

Customer delivery costs significantly impact profitability:

- Local delivery (same city): ₹30-50 per order

- Domestic shipping: ₹45-80 per order

- Express delivery: ₹80-150 per order

- Packaging materials: ₹8-15 per order

Cost Optimization Tip: Negotiate bulk rates with courier services once you reach 100+ monthly orders. Many entrepreneurs see 20-30% savings on shipping costs.

Optional Tools That Accelerate Growth

Professional Mockup Generation:

High-quality product images drive sales:

- Placeit Subscription: ₹2,000/month

- Adobe Stock: ₹1,500/month

- Custom Photography Setup: ₹15,000-40,000 one-time

Business Management Software:

Streamline operations as you scale:

- Order Management Plugin: ₹5,000-15,000/year

- Inventory Tracking: ₹3,000-8,000/year

- Customer Service Tools: ₹2,000-12,000/year

Social Media Marketing Tools:

Consistent online presence drives organic growth:

- Scheduling Tools: ₹1,500-5,000/month

- Analytics Platforms: ₹2,000-8,000/month

- Content Creation Apps: ₹1,000-4,000/month

Sample Investment Scenario: DTF-Based POD Startup

Let me walk you through a realistic startup scenario based on successful operations I’ve consulted:

Initial Investment Breakdown

- DTF Printer + RIP Software: ₹2,80,000

- Heat Press Machine: ₹22,000

- Website Setup: ₹18,000

- Design Software (Canva Pro): ₹4,000

- Initial Inventory (50 pieces): ₹12,000

- Miscellaneous (packaging, etc.): ₹8,000

- Working Capital: ₹25,000

Total Initial Investment: ₹3,69,000

Monthly Operating Costs

- Raw materials (100 pieces): ₹25,000

- Printing supplies: ₹15,000

- Website hosting/plugins: ₹2,000

- Marketing budget: ₹8,000

- Utilities and maintenance: ₹5,000

Monthly Operating Budget: ₹55,000

Revenue Projection (Month 6)

- Average selling price: ₹450 per piece

- Monthly sales: 180 pieces

- Gross revenue: ₹81,000

- Net profit (after all costs): ₹18,000-25,000

Breakeven Timeline: 4-6 months with consistent marketing and quality products

Cost-Saving Strategies for First-Time Entrepreneurs

Cost-saving strategies for first-time print-on-demand (POD) entrepreneurs include acquiring equipment wisely by opting for certified refurbished printers, which can save 30-50% compared to new machines, or utilizing lease-to-own programs with manageable down payments. Strategically outsourcing initial production by partnering with local service providers or established print shops for smaller runs helps validate demand and reduce upfront costs. Additionally, optimizing design and marketing by leveraging free tools like Canva, using smartphone photography, and focusing on high-margin, simple products such as t-shirts and basic hoodies can maximize early profitability while minimizing expenses.

Equipment Acquisition Tactics

Consider Refurbished Equipment: Save 30-50% on printing equipment by purchasing certified refurbished machines. I’ve helped clients find excellent DTF printers for ₹1.8 lakhs that would cost ₹3.2 lakhs new.

Lease-to-Own Programs: Some equipment suppliers offer monthly payment plans, reducing initial cash outlay to a ₹25,000-50,000 down payment.

Strategic Outsourcing Phase

Start with Service Providers: Before investing in equipment, test your designs using local printing services. This validates market demand while you save for equipment investment.

Partner with Established Printers: Negotiate wholesale rates with existing print shops for your first 100-200 pieces. Use profits to fund equipment purchase.

Design and Marketing Optimization

Leverage Free Resources:

- Use Canva’s free tier initially

- Create content using smartphone photography

- Build a social media presence organically before paid advertising

Focus on High-Margin Products: Start with t-shirts and basic hoodies before expanding to complex products. Master your core offerings first.

POD Profitability Analysis: Is It Worth It?

The POD profitability analysis highlights significant advantages over traditional retail, offering higher profit margins of 35-55% per sale, with zero inventory risk and no minimum order requirements. Real-world success stories, such as a Pune-based apparel brand, demonstrate how focusing on niche markets, maintaining quality, and consistent marketing can drive steady growth and sustainable profits. As order volumes increase, economies of scale further enhance margins through bulk discounts, optimized processes, and reduced shipping costs, making POD a compelling business model for entrepreneurs.

Margin Comparison with Traditional Retail

Traditional Fashion Brand:

- Wholesale cost: 40-50% of retail price

- Inventory risk: High

- Minimum orders: 500-1000 pieces

- Profit margin: 15-25% (after unsold inventory)

POD Model:

- Production cost: 25-35% of retail price

- Inventory risk: Zero

- Minimum orders: 1 piece

- Profit margin: 35-55% per sale

Real-World Success Story

One of my mentees, Rohit from Pune, started his gaming-themed apparel brand with a ₹2.8 lakh investment in DTF equipment. His journey illustrates POD potential:

Months 1-3: Learning curve, 15-30 pieces monthly. Months 4-6: Market validation, 60-100 pieces monthly. Months 7-12: Brand recognition, 150-250 pieces monthly. Current Revenue (Month 18): ₹1.4 lakh monthly with 35% profit margins

Key Success Factors:

- Focused niche (gaming community)

- Consistent social media presence

- Quality prioritization over price competition

- Customer feedback integration

Scaling Economics

As POD brands grow, economics improve dramatically:

100 pieces/month: 30-35% profit margins 300 pieces/month: 40-45% profit margins 500+ pieces/month: 45-55% profit margins

The improvement comes from:

- Bulk purchasing discounts on blanks

- Negotiated shipping rates

- Equipment amortization

- Process optimization

Essential Legal and Compliance Costs

Business Registration:

- Proprietorship Registration: ₹500-2,000

- LLP Registration: ₹6,000-15,000

- Private Limited Company: ₹10,000-25,000

Ongoing Compliance:

- GST Registration: Free (mandatory for business)

- Annual Compliance: ₹5,000-15,000

- Trademark Registration: ₹9,000-15,000 (recommended)

Payment Gateway Setup:

- Razorpay/PayU: 2-3% transaction fees

- UPI Integration: 0.5-1% fees

- Setup costs: Usually free with volume commitments

Strategic Investment Timeline

Phase 1: Validation (Months 1-3):

Investment: ₹50,000-1 lakh

- Outsourced printing for initial designs

- Basic website setup

- Social media presence building

- Market testing with 5-10 designs

Phase 2: Equipment Investment (Months 4-6):

Investment: ₹2.5-4 lakhs:

- Purchase printing equipment

- Expand design portfolio

- Implement order management systems

- Scale marketing efforts

Phase 3: Scaling (Months 7-12):

Investment: ₹1-2 lakhs additional

- Advanced marketing tools

- Inventory expansion

- Process automation

- Team hiring considerations

Conclusion: Maximizing Your POD Investment ROI

Design Excellence: Prioritize investing in unique, high-quality designs over expensive equipment initially. Exceptional designs sell well regardless of the printing method.

Brand Building: Allocate 15-20% of your budget to consistent branding and enhancing the customer experience. Strong brands command premium prices.

Customer Acquisition: Plan for customer acquisition costs over six months. While organic growth takes time, it helps build a sustainable business foundation.

Quality Consistency: Never compromise on print quality or garment selection. Reputation is built slowly but can be destroyed quickly.

The print-on-demand model has revolutionized fashion entrepreneurship in India, making it accessible to creative individuals regardless of traditional funding constraints. Success depends more on market insight, design quality, and consistent execution than on substantial capital investment.

Ready to transform your designs into a profitable apparel brand? Begin with thorough planning, smart budgeting, and a clear understanding of your target market. The opportunity is real, the investment is manageable, and the potential returns are substantial for those who approach it strategically.

Explore our complete guide to custom apparel printing in India for comprehensive insights into building a successful POD business, and check out our comparison of DTG vs screen printing to choose the right technology for your brand vision.